3D printed silica with nanoscale resolution

- Boyu Zhang

- Jul 17, 2023

- 2 min read

Silica is one of the most widely used inorganic materials that demands fabrication methods with nanoscale resolution in fields such as micro-electronics, micro-electro-mechanical systems and micro-photonics. To fabricate silica with desired nanostructures, complicated top-down fabrication methods are normally required. Although mature processing techniques with high yield have been developed, these techniques involve the use of hazardous chemicals and complex facilities for fabrication. Moreover, achieving intricate and/or asymmetric 3D architectures at nanometer resolution is very challenging using top-down fabrication methods.

The emerging technology of additive manufacturing can simplify fabrication processes and create complex architectures. However, there are two facts hinder the application of 3D printing. First, the relatively low spatial resolution offered by commercial 3D printing techniques limits their applications in micro-electronics, MEMS, and micro-photonics. Second, most of 3D printing techniques are designed for polymers. Although very few 3D printing techniques utilizing hybrid organic-inorganic materials and polymer-derived ceramics have been developed, the final parts often contain mixtures of carbon or nitrogen elements that present less controllable electrical properties and lack optical transparency. This hinders their applications in microelectronics and micro/nano-photonics.

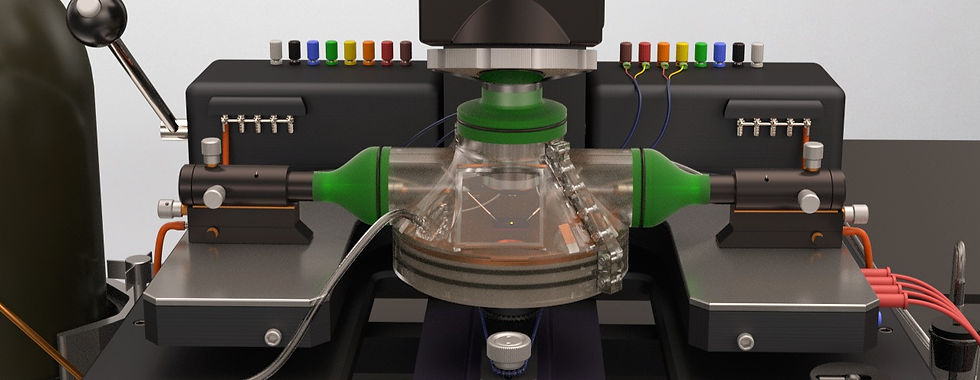

To address these limitations, we propose an approach to 3D print silica nanostructures with sub-200 nm resolution. The technique involves 2PP enabled 3D printing of well-dispersed poly (ethylene glycol) (PEG)-functionalized colloidal silica nanocomposite ink, followed by pyrolysis and sintering, where the post-processing procedure determines the crystallinity of the structures produced.

we demonstrate that the final 3D printed product is of pure silica with sub-200 nm resolution. Depending on the sintering temperature, the final silica structures can be either amorphous glass or polycrystalline cristobalite, suggesting tunability of the optical properties of the printed structures. Using nanoscale silica glass, we demonstrated that micro-toroid optical resonators fabricated using the proposed technology have quality factors (Q) over 10^4. Furthermore, we showed that doping and co-doping of rare earth salts can be directly implemented in the printed silica structures. The final doped silica glass nanostructure demonstrated strong photoluminescence at the desired wavelengths.

This method demonstrates the potential of building passive and active integrated micro-photonic chips with silica via 3D printing. It is also envisioned that arbitrary 3D structure of crystalline silicon can be fabricated by magnesium reduction of printed crystalline silica, making the dream of 3D printing silicon chips a reality.

See more details of this work:

Comments