Interfacial mechanical study of h-BN reinforced nanocomposites

- Boyu Zhang

- Jul 17, 2023

- 1 min read

Updated: Jul 25, 2023

Nanomaterials, such as carbon nanotubes, hexagonal boron nitride (h-BN) and graphene platelets, are promising candidates for reinforcing ceramic matrix composites. They are known for their high strength and have shown potential for improving the fracture toughness of monolithic ceramics. Much of the current understanding of these nano-reinforcements is based on extrapolation from the existing literature on much larger reinforcements such as microfibers. It is well established that crack bridging by micro- and nano-reinforcements is the dominant toughening mechanism, which requires interfacial sliding and failure along the interface between reinforcement and ceramic matrix. According to the studies on micro-reinforcements, the interaction between a crack and the interface is typically an energy governed process. However, in the case of nano-reinforcements, especially 2D reinforcements, this mechanism has yet to be fully explored due to the lack of systematic experimental studies on the interfacial properties of composites reinforced with nanomaterials.

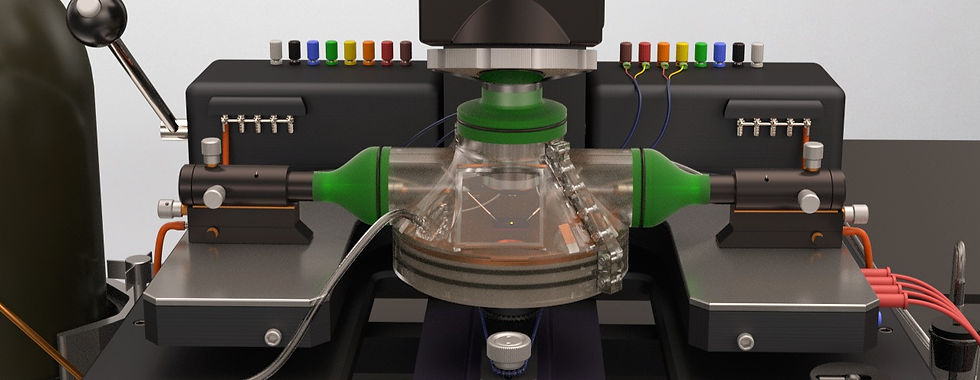

Herein, we developed an in-situ SEM tensile test setup to study the interfacial behaviors between multi-layer h-BN nanosheets and a polymer-derived ceramic (PDC). By using nanoindentation-assisted micro-mechanical

devices integrated with SEM, the detailed interfacial sliding and debonding behaviors between 2D materials and ceramic matrix were quantitatively measured for the first time. Based on the experimental observations, an analytical cohesive shear-lag model was established to understand the failure mode of the interface in h-BN/PDC composite. Furthermore, interfacial mechanical properties, i.e., interfacial modulus and strength, were calculated. It is found that the strength of the interface, rather than interfacial fracture energy, governs the interfacial failure at nanoscales, which provides valuable insight that is expected to motivate future work on the mechanical properties of nanomaterial-reinforced composites.

You can read this paper here:

Comments